Occasionally industry develops, or stumbles across, a transformative technology that revolutionises how a multitude of products are manufactured. Through a wide range of incredibly desirable attributes, the technology then gets embedded in everything and used everywhere.

Now imagine a technology that is so chemically and thermally stable, it can withstand a wide range of complex processes and applications. Something with outstanding durability, incredibly low surface tension, and low friction, as well as not only water repellent, but exceptional at repelling oil, grease, stains, and solvents. The end-use applications are only limited by a lack of imagination.

Think of all the products on the current marketplace that offer non-stick, wipe clean, stain resistance, waterproof, and water repellency. Think of any moving mechanical parts, such as bicycle chains, that require regular maintenance and lubrication. A surfactant that's also used in household cleaning agents and fire-fighting foams.

This technology exists and has, for over the last 70 years, been used in endless applications. Carpets, furniture, non-stick cookware, manufacturing machinery lubricants, cosmetics, paper straws, medical implants, even waterproof membranes, coatings and DWRs (Durable Water Repellents). The list is practically endless. The technology in question? PFAS (Per-and polyfluoroalkyl substances): a collection of several thousand chemical substances. This more recently adopted term covers a wide range of chemicals but includes PFOA (Perfluorooctanoic acid), PFOS (Perfluorooctanesulfonic acid), and PFC’s (Perfluorochemicals) or Perfluorinated Compounds.

The science behind PFCs

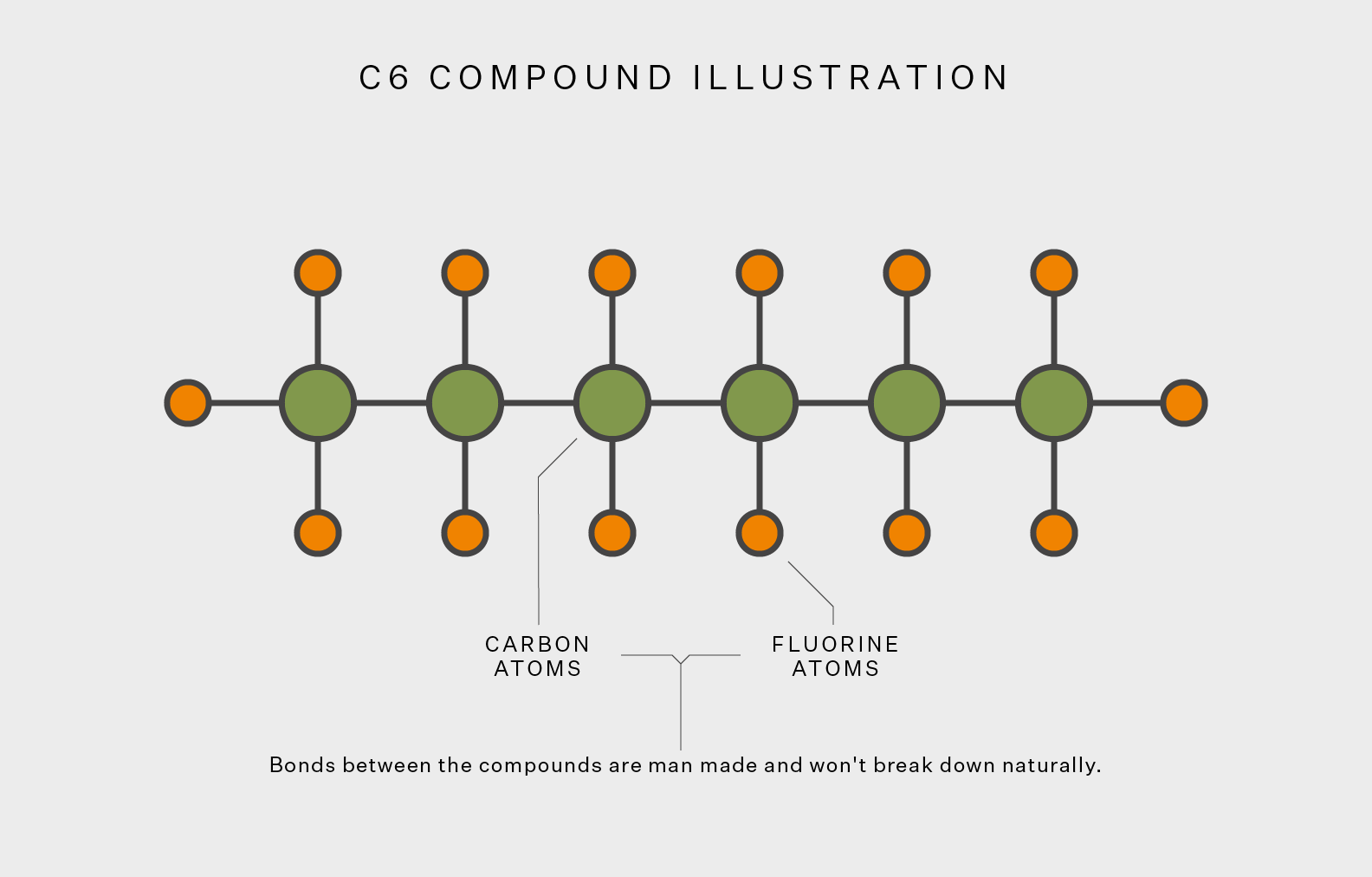

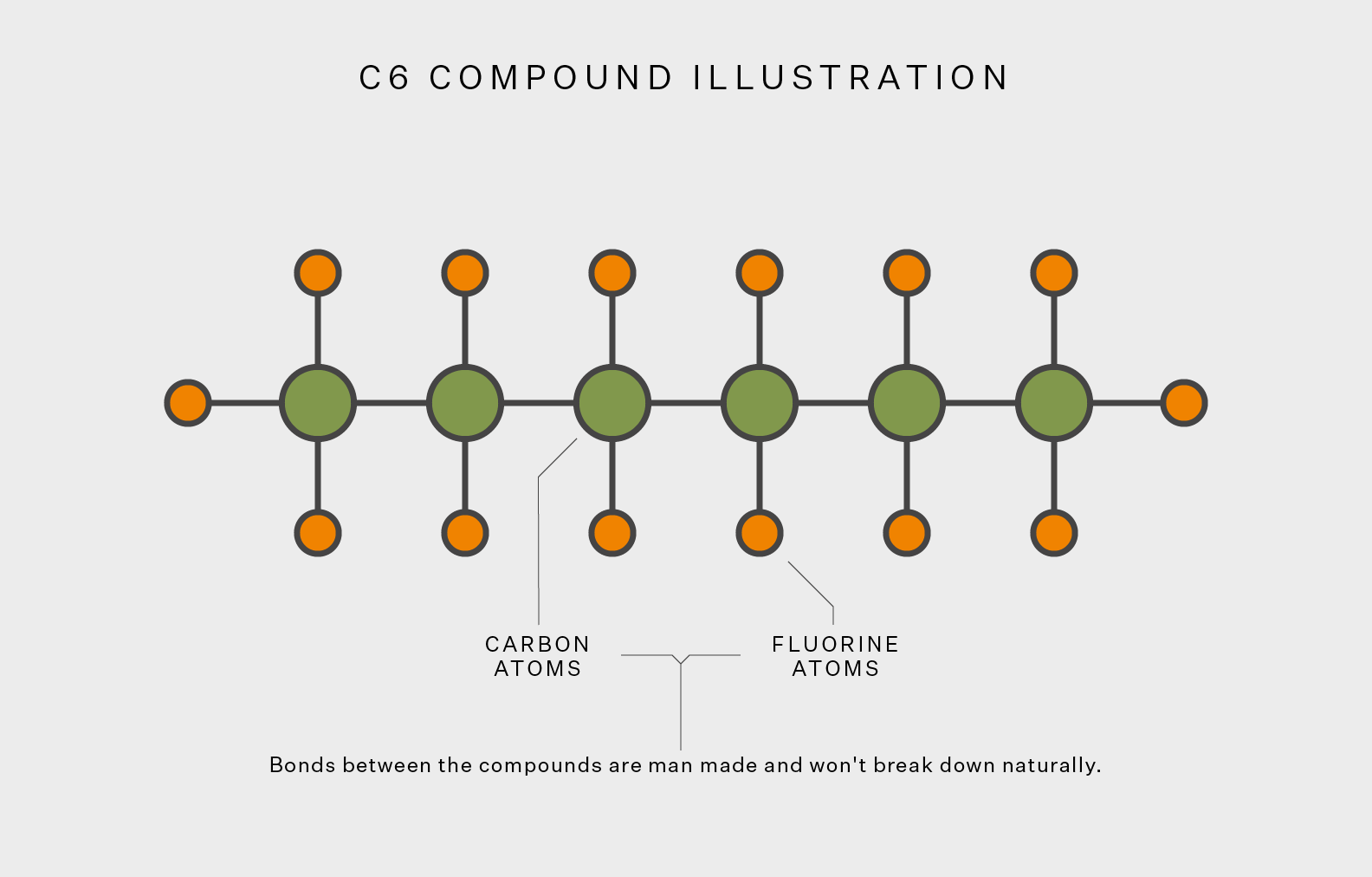

The Organisation for Economic Co-operation and Development (OECD) simplifies the PFAS definition to be Perfluoroalkyl and Polyfluoroalkyl Substances (PFAS) - synthetic chemicals defined as “fluorinated substances that contain at least one fully fluorinated methyl or methylene carbon atom”.

It all sounds very complicated, right? But a more simplistic view of these chemicals helps to define why they have been so durable and used so widely. In addition to their desirable attributes, they all have in common one of the strongest single bonds known to chemistry; the carbon-fluorine bond.

It is the strength of this C6 bond that has enabled these chemicals to be so durable and ultimately environmentally persistent, so much so, that they are occasionally referred to as “forever chemicals”. Depending on the amount of time and level of exposure, many of these chemicals have been shown to cause long-term health effects, as well as persisting in the environment indefinitely.

In short, to minimise the risk to both human and environmental health, all PFAS chemistries are coming under severe restrictions and regulations.

PFCs and outdoor gear

What does all of this mean when it comes to outdoor garments, packs and equipment? Going forward it will mean alternative, less harmful chemical substitutes. The manufacture of waterproof coatings and membranes are being re-engineered to avoid the intentional use and any potential cross-contamination of PFAS chemicals.

DWR’s are changing to PFAS-free variants. This of course is massively overly simplified, as alternatives may indeed be less damaging to health and the environment, however, they also do not share the same performance characteristics and durability of their predecessors.

As the industry comes to terms with a period of transition from old to new technology, it’s more important than ever to look after our outdoor clothing, treating it with love and care so it can perform to the highest level and maintain the levels of comfort we have become accustomed to.

Whilst good levels of water repellency are achievable with PFAS-free technologies, garments will no longer demonstrate stain and oil resistance. As attributes we don’t even realise we need to keep our garments looking at their best, the approach of washing garments more regularly will become the new norm.

Making sure DWR’s are well maintained and that water continues to bead and roll off our favourite waterproof jackets and trousers, is essential to optimum product performance, though not many people appreciate this is a key function to maximising comfort and the breathability of a waterproof garment. When waterproof garments wet out, the face textile becomes waterlogged, which reduces breathability. As the waterproof membrane cools, internal condensation within the garment increases, and causes discomfort. To maximize performance and comfort, make sure your DWR is functioning!

Paving the way for PFAS-Free

Montane has made significant headway in our transition to PFAS-free technologies and continues to learn daily about the new and complicated landscape we are living in. Legwear, synthetic, down insulation and softshell categories have already transitioned to PFAS-Free DWR’s. For spring summer 24 we have also introduced the Solution Waterproof Jacket and pants, our first step into PFAS-Free lightweight waterproof garments.

This is the start of a significant change to our waterproof jacket and trousers range which will come in Autumn Winter 25 with the rollout of Gore-Tex’s much anticipated new PFAS-Free ePE (expanded Polyethylene) membrane technology. Shortly after this, Montane will push to be entirely PFAS-Free as soon as feasibly possible. and of course in line with impending legislation.

An industrial transition of this size doesn’t happen overnight. It needs careful planning and consideration and presents significant new challenges with inevitably new solutions. New DWR’s behave differently with different textiles, and it certainly isn’t a one-size-fits-all approach.

We acknowledge there is a significant need to make radical industry changes, of which Montane are a comparatively small contributor. We are working tirelessly to better understand our impact so that we can take meaningful steps to correct our path.